Product Specifications

| Parameter | Details |

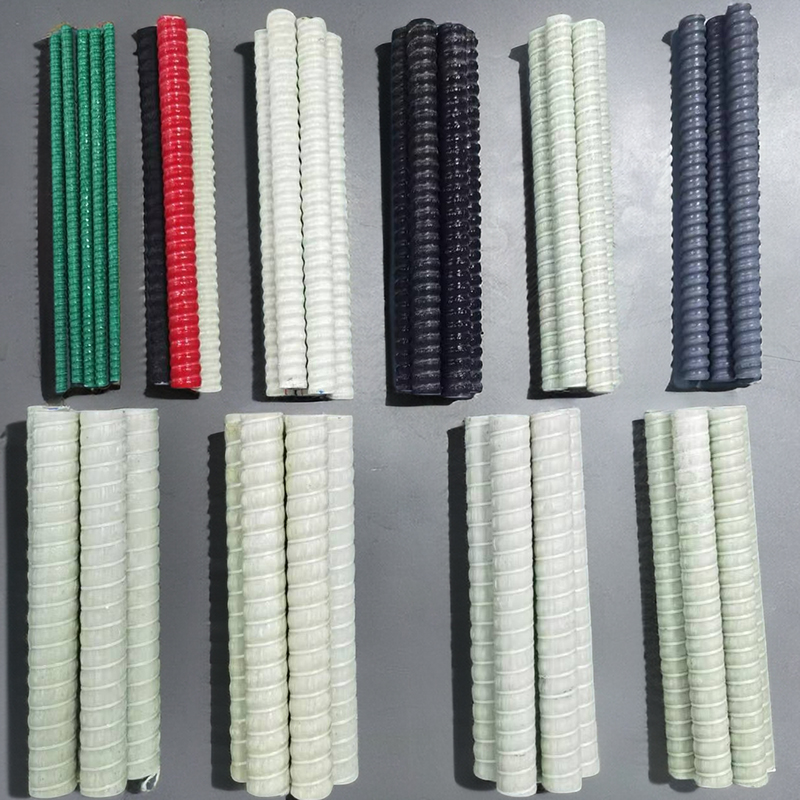

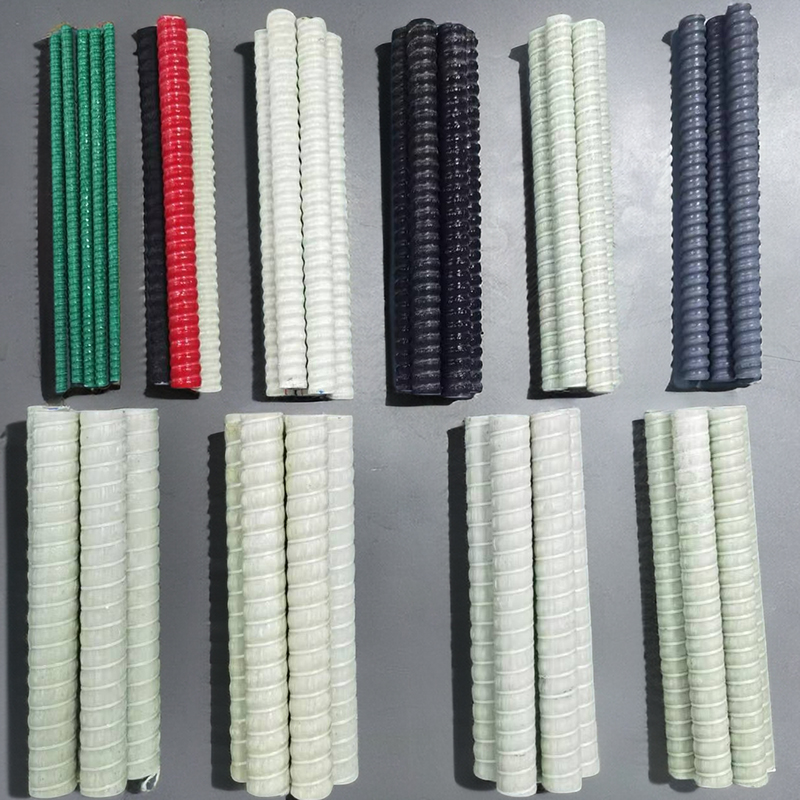

| Diameter | Φ3mm to Φ40mm, adjustable for different engineering requirements |

| Density | 1.5 ~ 1.9 g/cm³, about 1/4 of steel bars with the same volume |

| Strength | High tensile strength, suitable for diverse project requirements |

| Corrosion Resistance | Excellent resistance to acid, alkali, chloride ions, and low pH solutions |

The diameter of Glass FRP Rebar varies between Φ3mm and Φ40mm. This flexibility meets different engineering needs.

Its density ranges from 1.5 to 1.9 g/cm³. This is about a quarter of steel bars of the same volume. The lightweight design simplifies transportation and installation.

Glass FRP Rebar offers exceptional tensile strength. It fulfills the strength demands of diverse construction projects.

The material resists corrosion from acids, alkalis, and chemicals. It performs especially well against chloride ions and low pH solutions.

Choose Glass FRP Rebar for projects requiring strength and corrosion resistance.

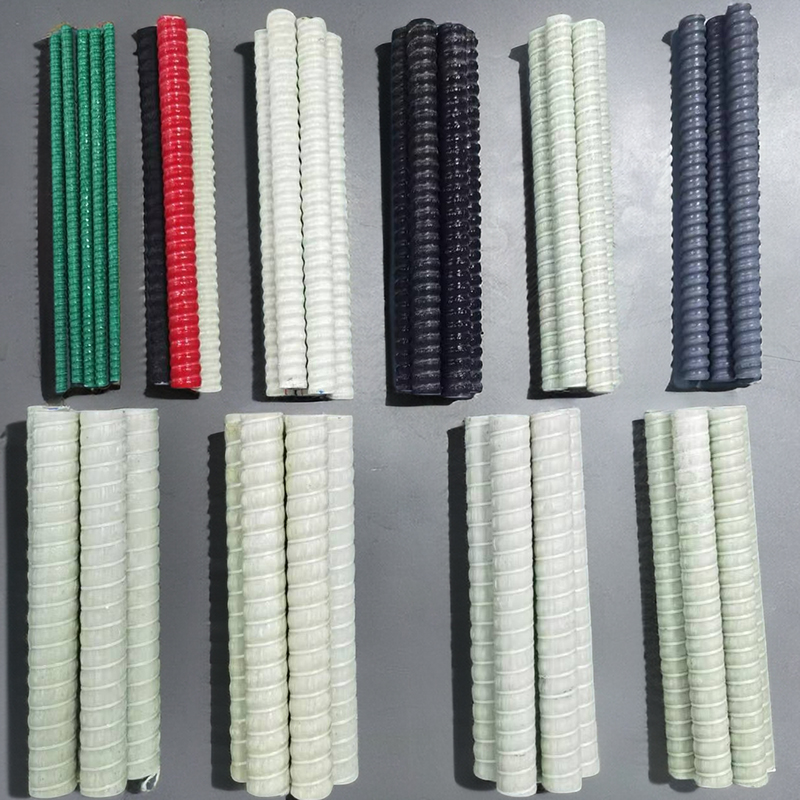

Glass Fiber Reinforced Polymer (GFRP) Rebar Features

Glass Fiber Reinforced Polymer (GFRP) Rebar is a high-performance composite material with the following characteristics:

1. High Strength

2. Corrosion Resistance

Resistant to chloride ions, acids, and alkalis, suitable for harsh environments like marine and chemical industries.

3. Lightweight

4. Electrical Insulation

5. Thermal Performance

6. Durability

7. Customizable Design

8. Eco-Friendly

9. Additional Properties

Resistant to pests, fatigue, and electromagnetic transparency, suitable for specialized engineering applications.

These features make GFRP Rebar an ideal high-performance alternative to traditional steel in modern construction projects.

Why Choose SNCM?

SNCM specializes in GFRP products, offering expertise and innovation to meet diverse project needs. Here's why you should choose us:

1. Rich Experience

2. Extensive Facilities

3. Technological Innovation

4. Strict Quality Control

5. High Parameter Standards

6. Independent Intellectual Property

7. Global Collaboration

SNCM combines innovation, quality, and expertise to deliver the best GFRP solutions.